Slide

Slide

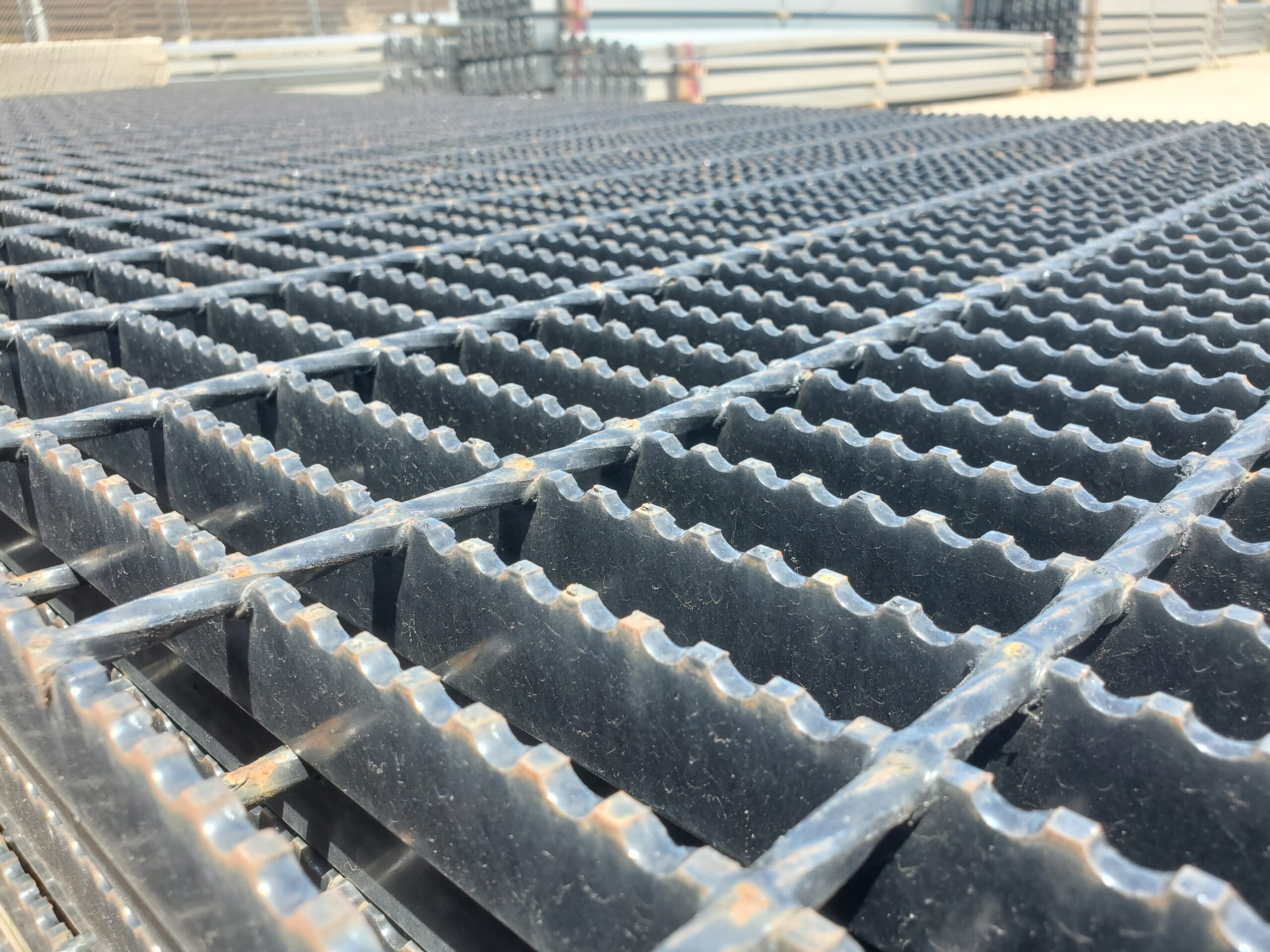

Full Service Safety Grating Fabricator

Slide

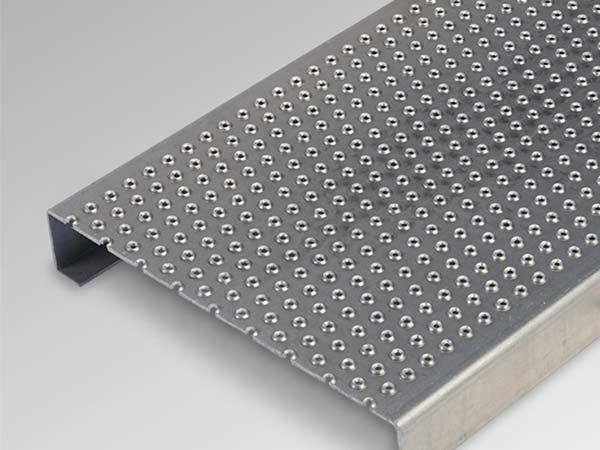

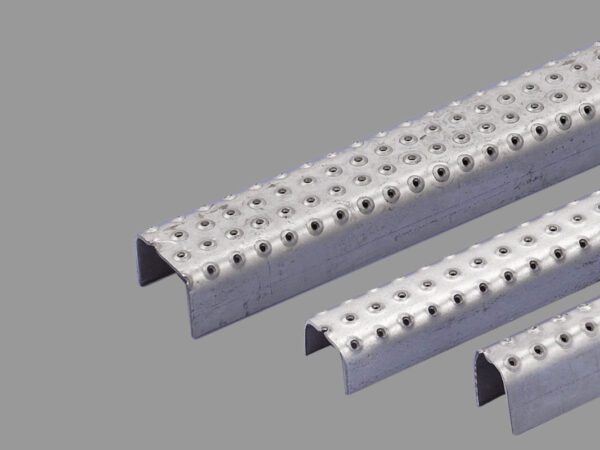

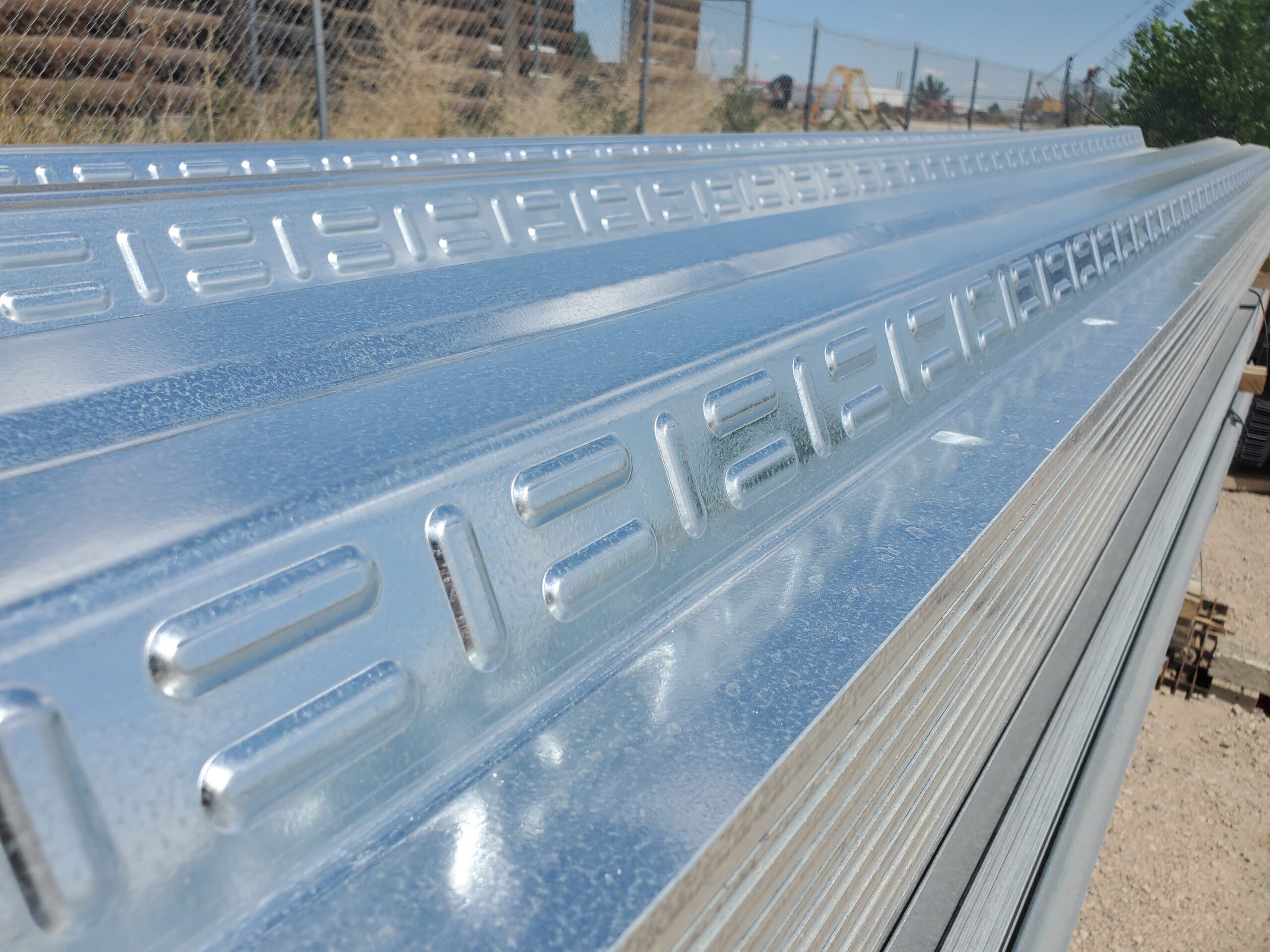

Roof & Floor Metal Decking Distributer

Slide

Full Service Metal Decking Distributor

Products

No matter the size of your construction project—whether you are building a large industrial complex or merely making some small property improvements, Drexel Supply Co. is the perfect source for your decking and bar grating needs.

Combining a thorough knowledge of the construction industry with personal yet professional approach to customer service, you get the right materials at the right price, right away.